Seamless tšepe tube bakeng sa Heat exchanger / Boiler pipe

Tlhahiso ea lihlahisoa

Qenching (Hardening, eo hape e tsejoang e le quenching) - ke mokelikeli o phahameng oa khatello ea metsi o futhumetseng ka mokhoa o ts'oanang ho mocheso o loketseng, ebe o qoelisoa ka potlako ka metsing kapa ka oli ka ho pholile ka potlako, kapa moeeng kapa sebakeng se batang, e le hore boiler bo matla ba khatello e phahameng. tube ho fumana boima bo hlokahalang.

Pipe ea boiler ea khatello e phahameng e tla senyeha ka mor'a ho tima.Ka nako e ts'oanang, khatello ea maikutlo e bakoang ke ho tima le ho pholile ho ka senya pipe ea boiler ea khatello e phahameng ka ho phatloha ha leseli.Ho felisa brittleness, mokhoa oa ho phekola o ka sebelisoa.Refire ke ho futhumatsa mocheso o phahameng oa boiler ho mocheso o loketseng kapa 'mala, ebe o fana ka serame se matla.Le hoja boima ba phala ea boiler bo phahameng bo fokotsehile hanyenyane, bo ka eketsa ho tiea ha pipe ea boiler ea khatello e phahameng le ho fokotsa brittleness ea eona.

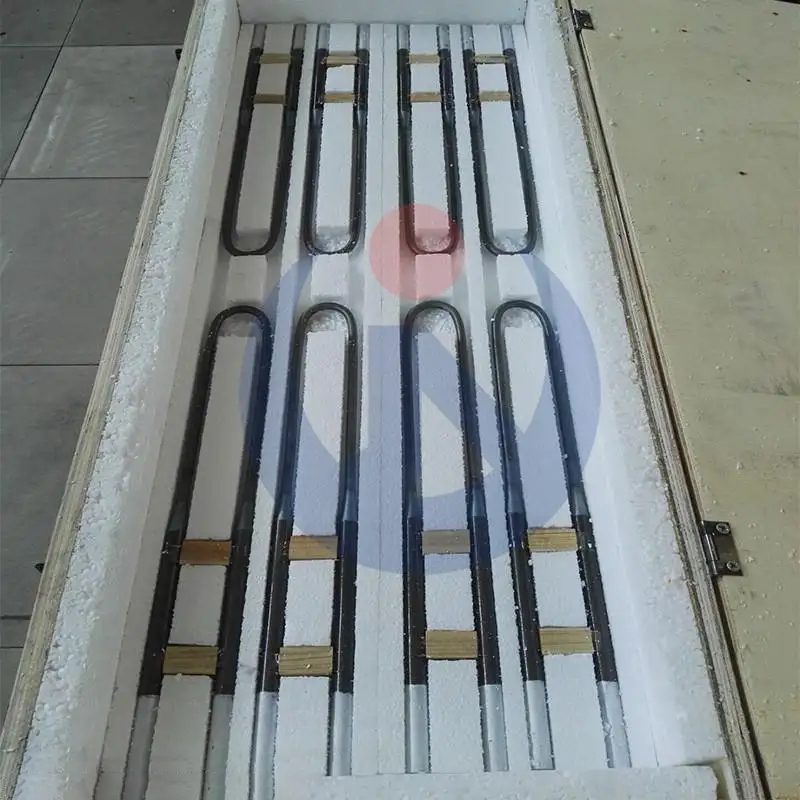

Annealing-annealing ke mokhoa oa ho felisa khatello ea maikutlo le tšepe ea pipe ea boiler ea khatello e phahameng.Annealing mokhoa ke ho futhumatsa likarolo tsa tšepe ho mocheso o boima, ebe o kenya molora o omileng, kalaka, asbestos kapa o koaletsoeng ka sebōping, etsa hore butle-butle u pholile.

Ho thatafala (bothata) - ke bokgoni ba ntho e hananang le ho kena kantle.The hardness tester e nepahetse haholo, e leng mokhoa o tloaelehileng oa ho lekola boima.Mokhoa o sebelisoang ka ho fetesisa oa tlhahlobo ke Rockwell hardness test mochini oa tlhahlobo oa ho thatafala oa Rockwell o sebelisa botebo ba daemane e potlakileng ka har'a tšepe ho fumana hore na bothata ba peipi ea boiler ea khatello e matla e kholoanyane, botebo ba ho kenella bo boholo, boima bo nyane.Taemane e potlakela botebong ba tšepe ho bontša palo e nepahetseng ho tloha ho pointer, e bitsoang nomoro ea thata ea Rockwell.

Forging-ke hamore ho etsa tšepe ka sebōpeho se itseng & lt;ho bopa & gt;mokhoa, ha khatello e phahameng ea boiler tube e futhumatsang mocheso oa forging, e ka kopanela ho qhekella, ho khumama, ho hula, ho bōpa le ho etsa mesebetsi e meng.Bongata ba li-boiler tubes tse nang le khatello e phahameng li bonolo ho qhekella ha li futhumatsoa ho ea bofubelu bo khanyang ba cherry.

Britittleness-e bonts'a mofuta oa phala ea boiler ea khatello e phahameng e bonolo ho phatloha, tšepe e entsoeng ka tšepe e brittle, esita le ho oela fatše ho tla phatloha.Britittleness le hardness li amana haufi-ufi, boima bo phahameng ba 20 # peipi ea tšepe e nepahetseng hangata le eona ke brittleness.

ductility- (hape e tsejoa e le bonolo) ke mofuta oa tšepe e sa feleng ka matla a kantle ntle le ho arohana, ductility ea phala ea boiler ea khatello e phahameng e ka huleloa ka mela e mesesaane.

Elastic-ke thepa ea khatello e phahameng ea boiler tube e holofalitsoeng ke matla a kantle, ha matla a kantle a felisitsoe.Tšepe ea selemo ke lintho tse rekerehang haholo.

Ho thatafala - ke ho hanyetsa tšepe ho phuncture kapa ho itšeha ka ntle ho ka eketsa khatello e phahameng ea boiler tube hardness mokhoa o tloaelehileng oa ho tima.

Performance- -e tsejoang hape e le malleability, ke sesupo se seng sa ductility ea tšepe kapa bonolo.Pontšo ke thepa ea tšepe e amohelang hamore e forang kapa e bilikang.

Toughness ke bokhoni ba phala ea boiler ea khatello e phahameng ho mamella ho thothomela kapa tšusumetso.Ho thatafala ho fapane feela le brittleness.

Ts'ebetsong ea tlhahiso ea phala ea tšepe e se nang mochini bakeng sa boiler, kalafo ea mocheso ke ts'ebetso ea bohlokoa.Phekolo ea mocheso e na le tšusumetso ea bohlokoa ho boleng ba ka hare le boleng ba holim'a phala ea tšepe e se nang seamless, e leng ea bohlokoa ka ho khetheha bakeng sa tlhahiso ea phala ea tšepe e se nang motsoako.

Khamphani ea rona e amohela kalafo ea mocheso e se nang oxidation, tlhahiso ea liphaephe tsa tšepe tse nang le mokhatlo o tsitsitseng oa metallographic le boleng bo botle ba kahare le kantle, e sebelisa eddy current le ultrasonic automatic flaw discovery, tšepe pipe e le 'ngoe bakeng sa ho lemoha liphoso tsa eddy hajoale le ho lemoha liphoso tsa ultrasonic.Ka tekanyo ea botenya ba ultrasonic le mesebetsi ea ho lemoha mefokolo ea oblique, e ka khona ho lemoha ka katleho liphoso tse entsoeng ka phala ea tšepe.

Lintlha tsa Sehlahisoa

| Sehlopha sa tšepe: | 106B,210A1,210C,P9,P11,T1,T11,T2,T5,T12,T22,T23,T91,T92,P235GH,13CrMo4-5,15Mo3,10CrMo9-10, ST35.8,ST45.8,STB340,STBA 12-2,API5L,5CT,ND-Steel Pipe |

| Tloaelo: | ASME/ASTM SA/A53/513/106/209/210/213/335/178/179/519 ASME/ASTM SA/A213,A312,A269,A778,A789, DIN 17456, DIN17457,DIN 17459,DIN17175,EN10216,BS3605,BS3059 |

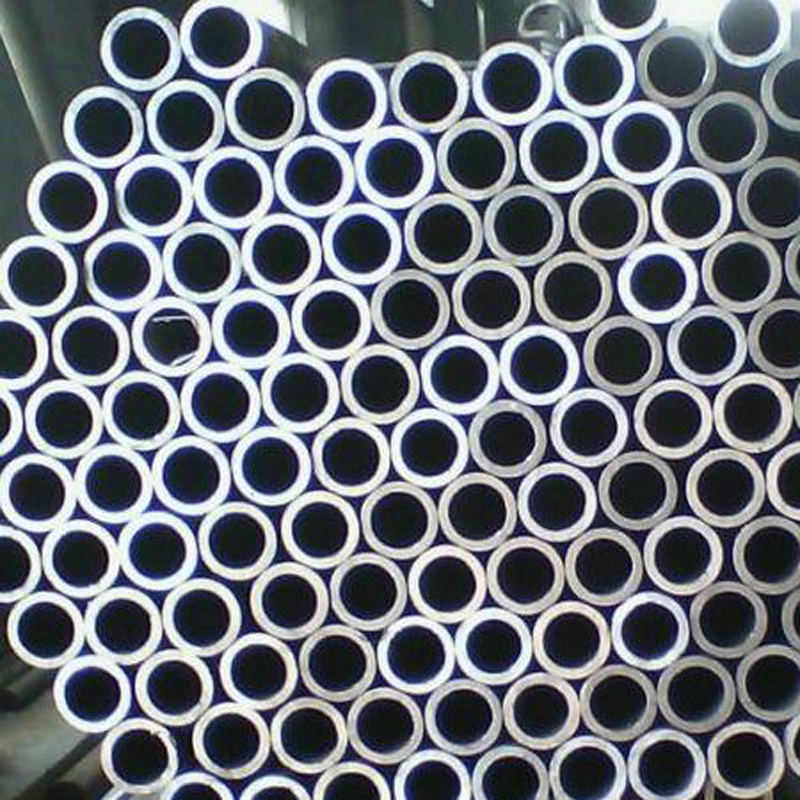

| Tlhaloso: | Kantle ho 10 ~ 508mm |

| Wt: | 1.0-30mm, kapa ho latela kopo e khethehileng ea moreki |

| Bolelele: | 2-20meters, kapa ho latela kopo e khethehileng ea moreki |

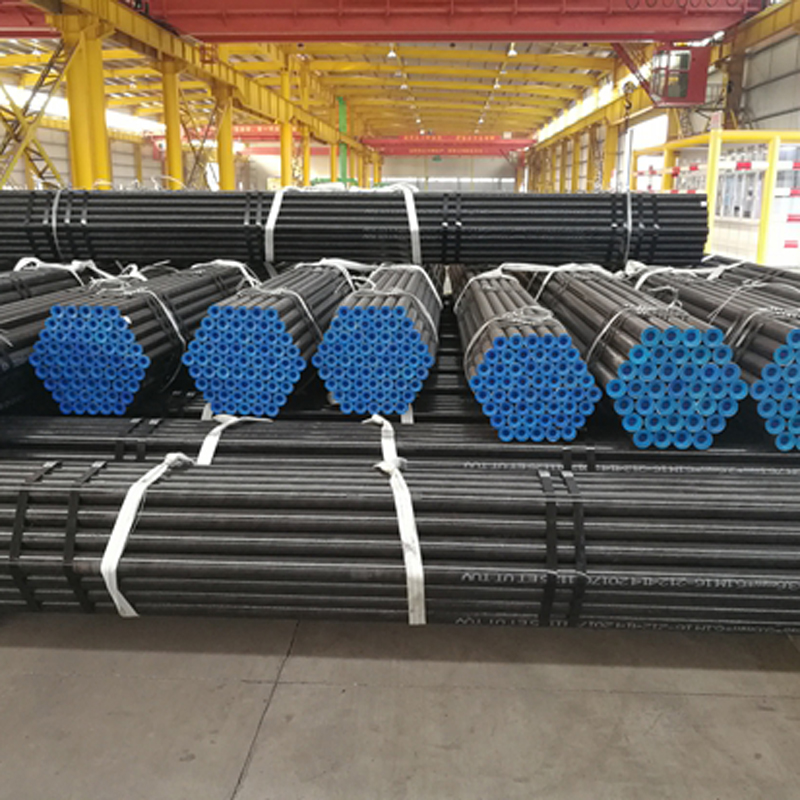

| Sephutheloana: | Export Standard Package |

| Mefuta ea li-tubes: | Boiler tube, peipi e nepahetseng, li-tubing tsa mochini, li-cylinder tube, lipeipi tsa mela, joalo-joalo |

| Mill MTC: | E fanoa pele e romelloa |

| Tlhahlobo: | Tlhahlobo ea Mokha oa Boraro e ka amoheloa, SGS, BV, TUV |

| Mount port: | Boema-kepe bofe kapa bofe China |

| Nako ea Khoebo: | FOB, CIF, CFR, EXW, joalo-joalo. |

| Nako ea Theko: | TT kapa LC ha u bona |

| Litšebeletso tsa rona: | Re ka itlhophisa ho latela tlhoko ea moreki kapa ho taka, ho paka ho latela kopo ea bareki |

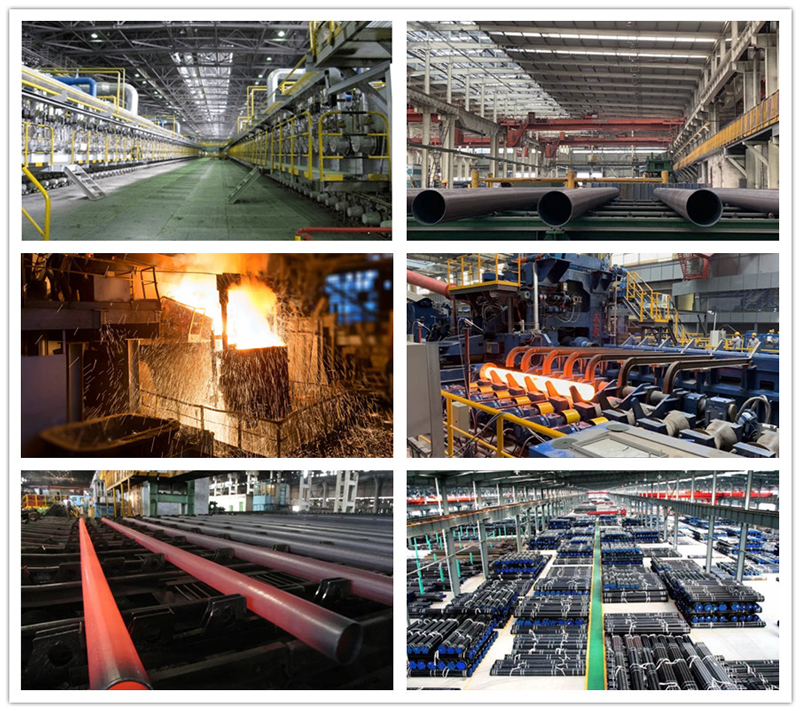

Fektheri Show