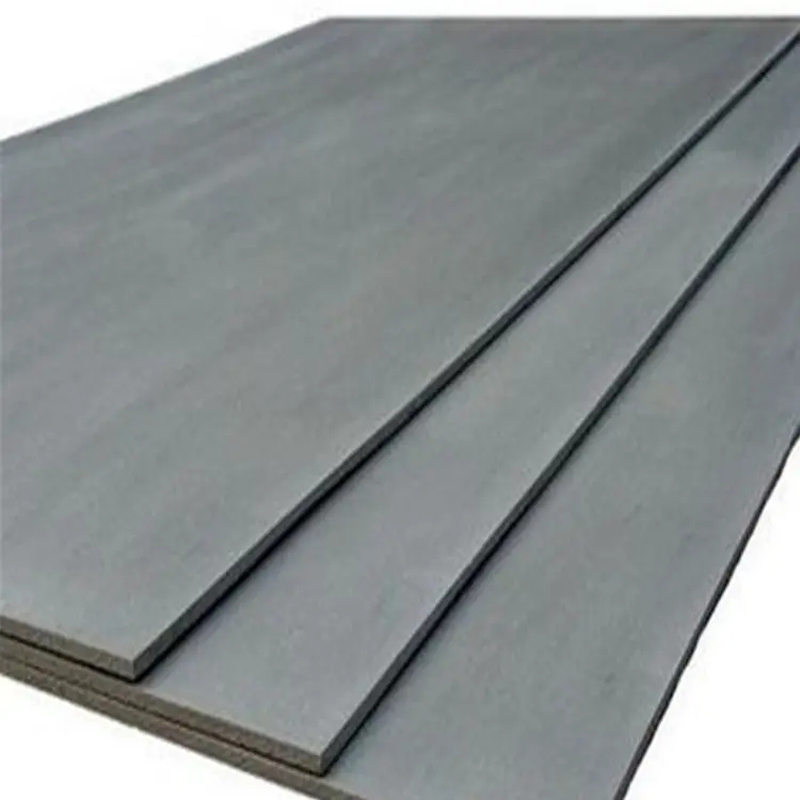

SA588 SA387 Alloy Steel Plate

Tšusumetso ea likarolo tsa alloy ka thepa ea ts'ebetso ea tšepe

1. Tšusumetso ea likarolo tsa alloy ka ts'ebetso ea tšepe ea tšepe

Mocheso o ka tlase oa mela e tiileng le ea mokelikeli 'me sebaka se fokolang sa mocheso oa crystallization ke, ho ntlafatsa ts'ebetso ea ho lahla.Tšusumetso ea likarolo tsa alloy ts'ebetsong ea ho lahla e itšetlehile haholo ka tšusumetso ea bona setšoantšong sa karolo ea Fe-Fe3C.Ho phaella moo, lintho tse ngata, tse kang Cr, Mo, V, Ti, Al, li etsa likarolo tse phahameng tsa melting carbide kapa oxide particles ka tšepe, e leng ho eketsang viscosity ea tšepe, ho fokotsa metsi, le ho senya ts'ebetso ea ho lahla.

2. Tšusumetso ea likarolo tsa alloy holim'a machining a polasetiki a tšepe

Ts'ebetso ea polasetiki e arotsoe ka ts'ebetso ea mocheso le ts'ebetso e batang.Lisebelisoa tsa alloy ho tharollo e tiileng, kapa sebopeho sa carbide (joalo ka Cr, Mo, W, joalo-joalo), e ntlafatsa ho hanyetsa ha mocheso oa tšepe ea tšepe le ho fokotseha ho hoholo ha thermoplasticity le ho qhekella habonolo le ho phatloha.Ts'ebetso ea ts'ebetso ea mocheso oa tšepe e tloaelehileng ea alloy e mpe haholo ho feta ea tšepe ea carbon.

3. Phello ea likarolo tsa alloy ho thepa ea welding ea tšepe

Lintho tsa alloy kaofela li ntlafatsa quenability ea tšepe, li khothalletsa ho thehoa ha lisele tse brittle (martensite), 'me li etsa hore ts'ebetso ea welding e be mpe.Leha ho le joalo, tšepe e na le palo e nyane ea Ti le V, e ka ntlafatsang ts'ebetso ea tšepe ea tšepe.

4. Tšusumetso ea likarolo tsa alloy holim'a ts'ebetso ea ho itšeha ea tšepe e amana haufi-ufi le ho thatafala ha tšepe, tšepe e loketse ho itšeha ho sebetsana le boima ba 170 HB ~ 230 HB.Ts'ebetso ea ho itšeha ea tšepe e tloaelehileng ea alloy e mpe ho feta ea tšepe ea carbon.Leha ho le joalo, tlatsetso e loketseng ea S, P, Pb le lintho tse ling e ka ntlafatsa haholo ts'ebetso ea ho itšeha ea tšepe.

5. Tšusumetso ea likarolo tsa alloy ts'ebetsong ea ts'ebetso ea mocheso oa tšepe ea tšepe

Ts'ebetso ea ts'ebetso ea phekolo ea mocheso e bontša bothata ba ho phekola mocheso oa tšepe le tšekamelo ea ho phekola mocheso.Haholo-holo e kenyelletsa quenability, overheating sensitivity, tempering embrittlement le oxidative decarbonization.Tšepe ea alloy e na le quenability e phahameng, 'me mokhoa o batlang o lieha oa ho pholisa o ka sebelisoa ha o tima, o ka fokotsang deformation le tšekamelo ea ho senya ea workpiece.Ho eketsa manganese le silicon ho tla eketsa kutloisiso e feteletseng ea tšepe.

Lintlha tsa Sehlahisoa

| Sehlopha sa tšepe: | 15CrMo, 12CrMoV, EN: S235JR, S275JR, S355JR, S420NL, S460NL, S500Q, S550Q, S620Q, S690Q ASTM: Grade B, Grade C, Grade D, A36, Grade 36, Grade 40, Grade 42, Grade 50, Grade 55, Grade 60, Grade 65, Grade 70, GradeJIS:SPHC, SS400, SPFC, SPHD, SPHE |

| Tloaelo: | DIN EN 10083,ASME SA516, ASTM A203M,ASME SA588,ASME SA387,SAE1045 JIS G4051,AISI, BS |

| Botenya: | 1.0-300mm |

| Bophara: | 100-4500mm, kapa ho latela kopo e khethehileng ea moreki |

| Bolelele: | 1-20meters, kapa ho latela kopo e khethehileng ea moreki |

| Sephutheloana: | Export Standard Package |

| Kopo: | 1.Machinery, liindasteri tsa likepe tsa khatello. 2.Mohaho oa sekepe, kaho ea Boenjiniere. 3.Koloi, Borokho, Mehaho. 4.Ho etsa mechine, Letlapa la Pavement, ect. |

| Mill MTC: | E fanoa pele e romelloa |

| Tlhahlobo: | Tlhahlobo ea Mokha oa Boraro e ka amoheloa, SGS, BV, TUV |

| Mount Port: | Boema-kepe bofe kapa bofe China |

| Nako ea Khoebo: | FOB, CIF, CFR, EXW, joalo-joalo. |

| Nako ea Theko: | TT kapa LC ha u bona |

| Litšebeletso tsa rona: | Re ka khaola le ho koba poleiti ea tšepe ho latela tlhoko ea moreki kapa ho taka, ho paka ho latela kopo ea bareki. |

Fektheri Show