Meqathatso ea Koporo, Letlapa la Koporo, Letlapa la Koporo, Letlapa la Koporo

Tlhahiso ea lihlahisoa

Koporo e hloekileng hammoho le nickel e ka ntlafatsa haholo matla, ho hanyetsa kutu, ho thatafala, ho hanyetsa le thepa ea thermoelectric, le ho fokotsa coefficient ea mocheso oa resistivity.Joalo koporo e tšoeu ho feta lisebelisoa tse ling tsa mochini oa alloy alloy, thepa ea 'mele e ntle haholo, ductility e ntle, boima bo phahameng le mmala o motle, ho hanyetsa kutu, thepa e matla ea tšusumetso e tebileng, e sebelisoa haholo kahong ea likepe, petrochemical, lisebelisoa tsa motlakase, lisebelisoa, lisebelisoa tsa bongaka, lisebelisoa. , litlhoko tsa letsatsi le letsatsi, mesebetsi ea matsoho le masimo a mang, 'me ke khanyetso ea bohlokoa le motsoako oa thermocouple.Bofokoli ba koporo e tšoeu ke hore ntho e ka sehloohong ea ho eketsoa -- nickel ke ntho e haellang ea leano, 'me theko e batla e theko e boima.

Brass ke motsoako o entsoeng ka koporo le zinki.Brass e entsoeng ka koporo le zinki e bitsoa koporo e tloaelehileng.Haeba e entsoe ka likarolo tse fetang tse peli, e bitsoa koporo e khethehileng.Brass e na le khanyetso e matla ea ho apara, koporo e atisa ho sebelisoa ha ho etsoa li-valve, liphaephe tsa metsi, moea oa moea ka hare le ka ntle ho phala ea ho kopanya mochine le radiator.

Koporo e pherese, eo hape e tsejoang e le koporo e khubelu, e na le conductivity e ntle haholo ea motlakase le conductivity ea mocheso, polasetiki e ntle haholo, e bonolo ho khatello ea mocheso le ts'ebetso ea khatello e batang, mohala o mongata, mohala, borashe, spark e khethehileng ea koporo ea electrocorrosion le litlhoko tse ling tsa conductivity e ntle. lihlahisoa.

Motlakase oa motlakase le mocheso oa mocheso oa koporo o pherese ke oa bobeli ho silevera, o sebelisoang haholo ho hlahisa thepa ea conductive le ea mocheso.Koporo e na le khanyetso e ntle ea kutu sepakapakeng, metsing a leoatle le asiti e seng ea oxidized (hydrochloric acid, dilute sulfuric acid), alkali, tharollo ea letsoai le mefuta e fapaneng ea li-organic acid (acetic acid, citric acid), mme e sebelisoa indastering ea lik'hemik'hale. .Ntle le moo, koporo e na le ts'ebetso e ntle ea weldability, e ka bata, e sebetsa ka thermoplastic ho ba lihlahisoa tse fapaneng tse felileng le lihlahisoa tse felileng.Lilemong tsa bo-1970, tlhahiso ea koporo e pherese e ile ea feta kakaretso ea mefuta e meng eohle ea lisebelisoa tsa koporo.

Lintlha tsa Sehlahisoa

| Lebitso la Sehlahiswa | Mekhoro ea Koporo |

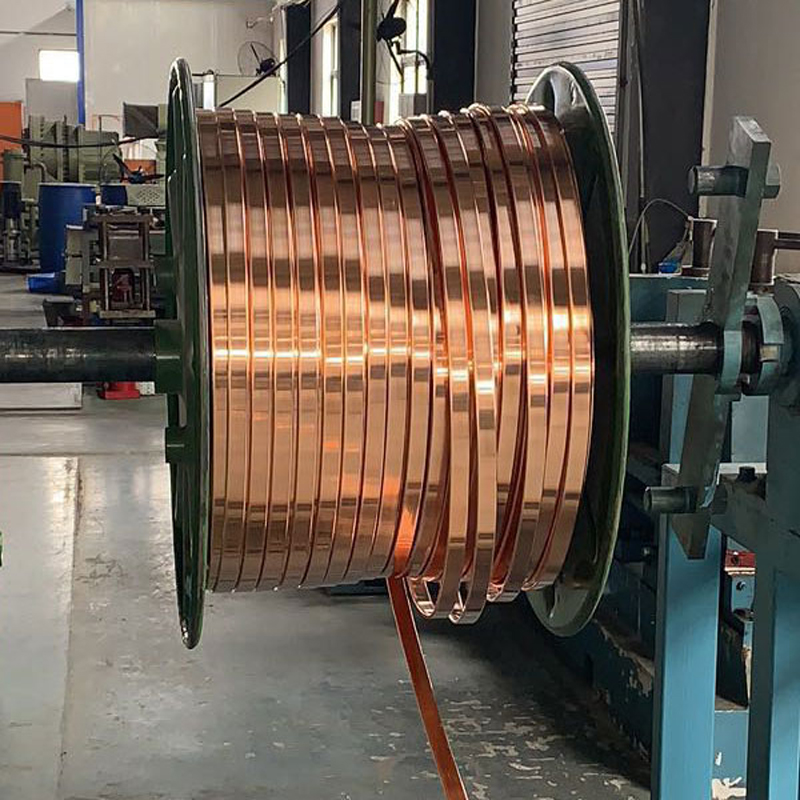

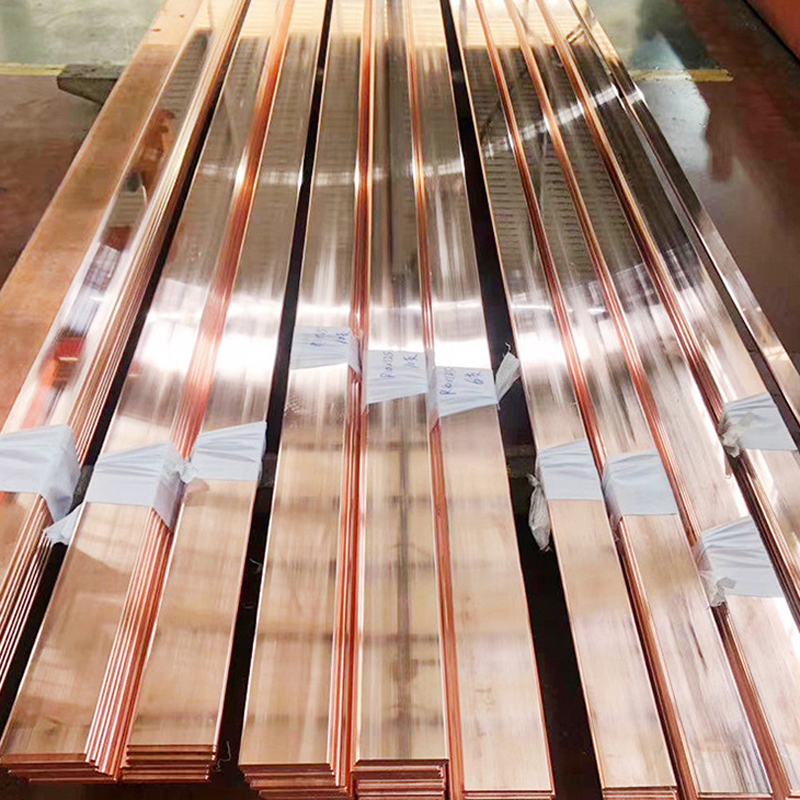

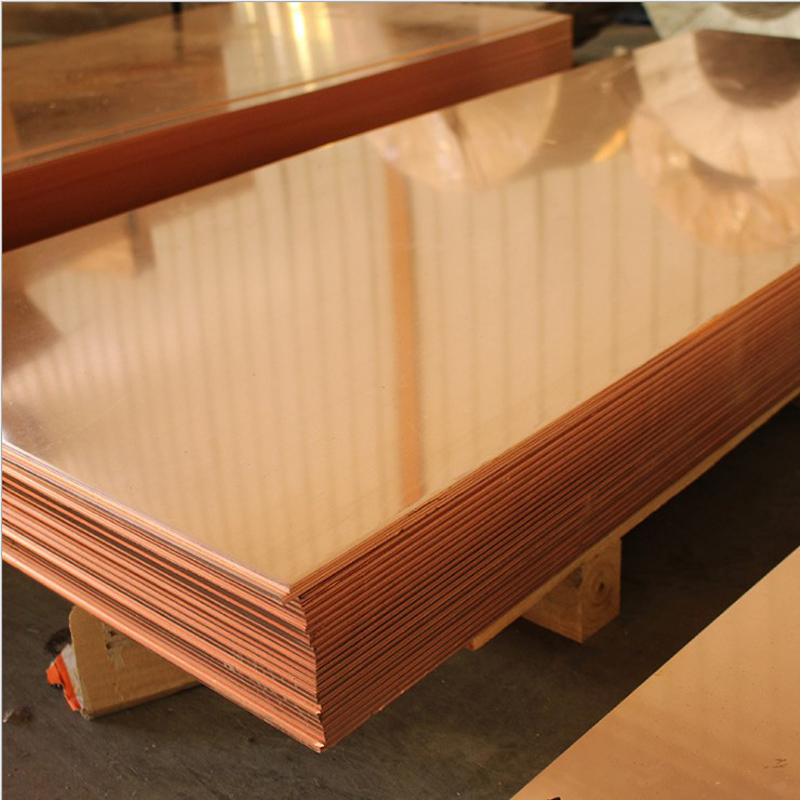

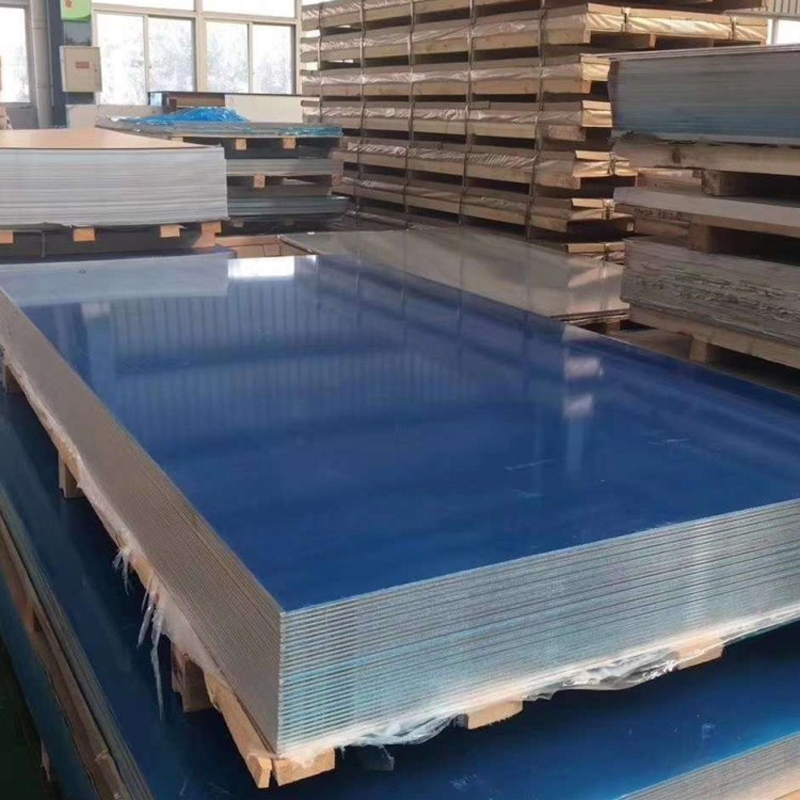

| Sebopeho | Coil/Strip/Plate/Sheet/Bar/Rod/Pipe/Tube/Wire |

| Boholo | Boholo ba kamehla 600x1500mm kapa Customized |

| Kereiti | Koporo e Hloekileng:C10100/C10200/C11000/C12000/C12200 Alloy ea Koporo:C14500/C17200/C17300/C17510/C18150/C19200/C19210/C19400 Koporo:C22000/C23000/C24000/26000/26800/27000 Brass e etellang pele:C33000/CuZn36Pb3/C35000/C35300/C36010/C37000/37700/C38000/C38500/CuZn39Pb3/CuZn40Pb2 Tin Brass:C44300/C44500/C46400/HSn90-1 Aluminium Brass:C68700/HAl77-2/HAl66-6-3-2/HAl64-3-1 Tin Bronze:C51000/C51100/C51900/C52100/C54400/CuSn4/CuSn5/CuSn5Pb1/CuSn6/CuSn8 Aluminium Bronze:C60800/C61300/C61900/C62300/C63000 Copper Nickel Alloy:C70400/C71500/C70600/C70620/C73500/75200/76200/C77000H59,H62,H63,H70,H80,H90,H96,TU0-TU0-TU2,Q3B-1,H96,TU0-TU0-1B3,SQ3B1,SQ3B1 n15- 20 CuBe2 |

| Standard | ASTM B280/B111/B152/B88/B49/B359/B505 |

| Khalefo | H,1/2H,3/4H,1/4H,EH,SH,O60 joalo-joalo. |

| Bokaholimo | Mill, e bentšitsoeng, e khanyang kapa e hlophisitsoeng. |

| MOQ | 100kg |

| Nako ea thomello | Matsatsi a 5-10 ka mor'a hore tefo e amoheloe |

| Tefo | 30% TT deposit + 70% TT ho leka-lekana pele ho pepa |